How To Cut Rubber Edge Trims

If you’ve just purchased or are about to purchase some of our flexible edge trim (click here to view them all) you maybe wondering how best to cut them to your desired length. Fear not! Below are some handy hints and tips on How To Cut Rubber Edge Trims and this is actually how we cut them before sending them out to customers. As we often get asked, ‘what is the best way to cut these’?

Our range of edge trims feature a segmented Steel spine which is embedded into the PVC rubber. This allows the trims to be flexible without kinking when it’s run around a corner or bend. It also helps the trim grip the panel edge and give it a more robust feel. What this means though is that unless you know the trick way to cut them, they can be a pain to trim.

Need the right tool for cutting these? Click here.

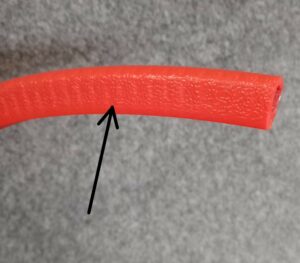

As you can see, highlighted in the below images, the outlines of the spine can be just about seen from the exterior of the trim. Flip it over and it becomes even more obvious.

Some of the trims, especially the larger sizes, are easier to cut from underneath as the segments of the spine are easier to see.

What you’re aiming to do it to slice between the segments which creates a neat cut.

Using snips or a sharp blade in a knife, start by gently pressing on the PVC rubber outer where you think you’re between two segments. The snips will either slice nicely through it or there will be some resistance – which is when you’ve cut into metal, so move along a mm or so until it easily cuts through the rubber and between the segments. As shown below.

And there you have it! A neat, clean cut through your edge trim. That’s How To Cut Rubber Edge Trims.

If you do mess it up, and end up cutting where the metal is, you can pull the metal segment out from the end of the trim. It doesn’t look as neat but if this happens by accident, it can be done and then the trim can be cut back neatly.

Don’t forget to checkout our full range on edge trims including various coloured trims too, click here to view.

If you don’t fancy using these types of trims or these are maybe not quite suitable for your project, take a look at our Rubber U-Channels, click here.